|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Old Transformer Oil Purification Oil Purifier Oil Separation Plant

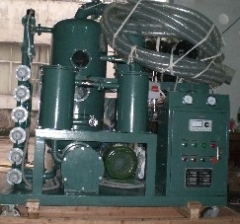

Old Transformer Oil Purification Oil Purifier Oil Separation Plant

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Brand Name:

ZN

Production Capacity:

100

Delivery Date:

15 DAYS

ZYD is special for treating the used and old transformer oil, mutual oil, switch oil.

ZYD has been specially designed for on site use to completely regenerateinsulating oils in energized or de-energized transformers

Application:

ZYD has been specially designed for on site use tocompletely regenerate insulating oils in energized or de-energized transformerseven when transformer power above 110KV and altitude over 500 meters, as well aspurify mutual inductor oil, switch oil and so on.

These equipment aresuitable for cleaning of contaminated transformer oil, cable oil and insulatingoil,etc. Depending on type contamination equipment are designed usingcombination of processes such as vacuum oil purifying, degassification,coalescing and filtration

Meanwhile, Series ZYD oil purifier can be used asindependent vacuum source with functions of vacuum drying and vacuum oiling.

Features:

1. Double-stage vacuum system, strong power of vacuumevacuating, ultimate vacuum value < 5Pa 2. Two vacuum separating chambers,efficient oil film sprayer, increasing separating size and separating time toensure the dry-level and dielectric strength improving greatly. 3. High VacuumTower With Coalescer Elements 4. Duplex-Stereo film evaporation technology,combined with unique and advanced dewatering, degassing components, can rapidlyand effectively separate water, gas from oil. 5. Multi-stage precisionfiltration system, mesh filtration combined with molecular adsorptiontechnologies 6. Efficient electric heating system, heating uniformity, lesspower consumption, safe, and reliable. 7. Double-infrared liquid level sensor,pressure protective system to ensure machine operation easy and safely.

Advantage:

Comparing with the single-stage type, this machine adoptsthe double stages vacuum system, which can improve the machines working vacuumvalue highly, so it can dewater, degas and remove the impurity more deeply andeffectively. The dielectric value of treated oil is higher than 75 KV. It isvery suitable for the large electric & insulation equipments.

ZHONGNENG manufactures and offers a variety of systems designed fordegasification, cleaning, drying, regeneration, purification, recycling,filtration , recovery, removal of water and particulate matter from transformer,turbine, cable and other oils. The company employs staff of high skilledengineers and constructors whose efforts are aimed at constant developing,improving and modernizing of the production. The company responds flexibly toclients' requirements. We are able to customize equipment upon specifictechnical needs of our customers.

ZYD has been specially designed for on site use tocompletely regenerate insulating oils in energized or de-energized transformerseven when transformer power above 110KV and altitude over 500 meters, as well aspurify mutual inductor oil, switch oil and so on.

These equipment aresuitable for cleaning of contaminated transformer oil, cable oil and insulatingoil,etc. Depending on type contamination equipment are designed usingcombination of processes such as vacuum oil purifying, degassification,coalescing and filtration

Meanwhile, Series ZYD oil purifier can be used asindependent vacuum source with functions of vacuum drying and vacuum oiling.

Features:

1. Double-stage vacuum system, strong power of vacuumevacuating, ultimate vacuum value < 5Pa 2. Two vacuum separating chambers,efficient oil film sprayer, increasing separating size and separating time toensure the dry-level and dielectric strength improving greatly. 3. High VacuumTower With Coalescer Elements 4. Duplex-Stereo film evaporation technology,combined with unique and advanced dewatering, degassing components, can rapidlyand effectively separate water, gas from oil. 5. Multi-stage precisionfiltration system, mesh filtration combined with molecular adsorptiontechnologies 6. Efficient electric heating system, heating uniformity, lesspower consumption, safe, and reliable. 7. Double-infrared liquid level sensor,pressure protective system to ensure machine operation easy and safely.

Advantage:

Comparing with the single-stage type, this machine adoptsthe double stages vacuum system, which can improve the machines working vacuumvalue highly, so it can dewater, degas and remove the impurity more deeply andeffectively. The dielectric value of treated oil is higher than 75 KV. It isvery suitable for the large electric & insulation equipments.

ZHONGNENG manufactures and offers a variety of systems designed fordegasification, cleaning, drying, regeneration, purification, recycling,filtration , recovery, removal of water and particulate matter from transformer,turbine, cable and other oils. The company employs staff of high skilledengineers and constructors whose efforts are aimed at constant developing,improving and modernizing of the production. The company responds flexibly toclients' requirements. We are able to customize equipment upon specifictechnical needs of our customers.

Related Search

Transformer Oil Purification

Oil Purification Plant

Transformer Oil Purifier

Vacuum Transformer Oil Purifier

Oil Purification

Old Master Oil Painting

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)