|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Dielectric Oil Purifier, Dielectric Oil Treatment, Dielectric Oil Filtration Unit, Dielectric Oil Filtering System

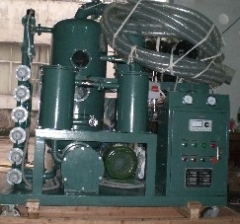

Dielectric Oil Purifier, Dielectric Oil Treatment, Dielectric Oil Filtration Unit, Dielectric Oil Filtering System

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Brand Name:

ZN

Production Capacity:

100

Delivery Date:

15 DAYS

ZYD is special for treating the used and old transformer oil, mutual oil, switch oil.

Application:

Zhongneng High voltage transformer oiltreatment, electrical life are brought equivalent in new transformer oil.Transformer oil regeneration process can be eliminate acid, moisture, gas,sediment, filter particles from the oil with the thermo-vacuum system andimprove the quality.

This machine is widely used in all industrysuch as power plants, power stations, power companies, metallurgy, petrifaction,machinery, traffic, railways etc. Especially for on site transformer overhaulingwith 110 KV or over.

Features:

1.Double-infrared liquid level sensor, pressure protective system to ensuremachine operation easy and safely.

2.High speed two- stage vacuum system can vacuities for transformer's on siteinstallation or overhauling, finish removing gases, water, discolorsimultaneously, shorten period of oil treatment.

3. Unique degas,dehydration, depolarization system, adopt stereo-evaporation technology, highefficiently remove water, gases, impurities from transformer oil, improve oilquality and dielectric strength.

4. Fine filtration system, five- layeragglomeration filtration from Japan, and super high fine filtration from USA, incombination with several stages of screens with mesh size reduced stage bystage. The filtration precision gets to international standard; NAS 4 Class .Thelife of filtration is more than one year.

5. Excellent configure; Mainfittings from USA, Germany, France, Italy, etc and electrical system importedwith original packing, ensure this machine can run safely with high performanceand can continuously run about 720 hours.

6. High autoimmunization: adoptPLC full automatic system, operate by touching screen, with dynamic display andcan connect computer to operate.

3. Unique degas,dehydration, depolarization system, adopt stereo-evaporation technology, highefficiently remove water, gases, impurities from transformer oil, improve oilquality and dielectric strength.

4. Fine filtration system, five- layeragglomeration filtration from Japan, and super high fine filtration from USA, incombination with several stages of screens with mesh size reduced stage bystage. The filtration precision gets to international standard; NAS 4 Class .Thelife of filtration is more than one year.

5. Excellent configure; Mainfittings from USA, Germany, France, Italy, etc and electrical system importedwith original packing, ensure this machine can run safely with high performanceand can continuously run about 720 hours.

6. High autoimmunization: adoptPLC full automatic system, operate by touching screen, with dynamic display andcan connect computer to operate.

Related Search

Dielectric Strength

Dielectric Strength Tester

Gps Dielectric Antenna

Filtering Oil System

Oil Filtration System

Oil Treatment Unit

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)