|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Transformer oil regeneration oil filtering oil purify system

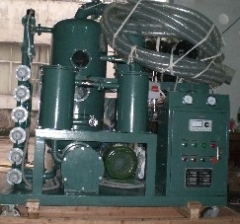

Transformer oil regeneration oil filtering oil purify system

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Structure:

Vacuum Filter

Material:

Others

Production Capacity:

100

Delivery Date:

15 DAYS

Function:

Oil Filter

Brand Name:

ZN

Transformer Oil Filtration Plant, specially used for filtering transformer oil, insulating oil.

Series ZYD-III Highly vacuum Transformer oil regeneration machine is used foroverhauling and installing the electric insulating equipments which can runningas energized, such as transformer, oil switch, and mutual inductor. Also it isespecially applied to regenerate and purify the seriously exhausted insulatingoil and make the oils reach the international standard. As a special equipmentfor dehydration, degassing, purification process of various kinds of insulatingoils in electrical transformers and circuit breakers etc. It is designed onvacuum drying principle, coalescence and separation technique, accurate finefiltration and other Zhongnengs'patented technique.

The oil technicaldata after treatment:

A. Gas content is less than 0.1%

B. Impurity degreeis less than 1μm without free carbon

C. Oil dielectric strength (breakdownvoltage) is more than 75KV

The oil technicaldata after treatment:

A. Gas content is less than 0.1%

B. Impurity degreeis less than 1μm without free carbon

C. Oil dielectric strength (breakdownvoltage) is more than 75KV

D. Water content is less than 3 part per million

E. Acidity value is lessthan 0.01 mgKOH/g

F. Dielectric loss factors at 90°C is less than 0.001

E. Acidity value is lessthan 0.01 mgKOH/g

F. Dielectric loss factors at 90°C is less than 0.001

G. Cleanliness degree is less than NAS 1638 Grade5

Features:

1. Besides the common vacuum oilpurifier's function of dewatering, degassing, and eliminating impurities, thismachine can regenerate the seriously exhausted oil by removing the polaritymaterials, such as deep oxides, free carbon in the oil effectively. It can makethe seriously exhausted oil reach the normal index like anti-oxidation,acid-base water-solubility.

2. Three ways of using: the vacuum dewatering,degassing, removing impurities system can work independently, so does theregeneration oil system, and also they can work at the same time.

3.Double-stage, high vacuum pressure and high flow rate that help remove water,air, gases, solid particulates and other impurities from oil quickly andefficiently so as to improve the breakdown voltage of oil and maintain itsinsulating property.

4.Advanced dehydrating and degassing system that uselarge area three-dimension flash distillation technique to remove harmfulcomposition in the oil, such as water, air and gases.

5. Precise finemulti-stage filtration helps remove mechanical impurities in oil, high qualityfilter elements is of corrosion proof, strong mechanical strength and wearresistance.

6.The machine adopts the double-infrared liquid automaticcontroller, sensitive automatic pressure protector and the high effectiveequipment for degas, so it is easy to operate.

7. Carbon fiber infraredheating system that can make the oil contains zero sum of ethyne aftertreatment.

8. The oil of any grades can be treated on line at the workingsite.

9. The Automatic oil purifier model is installed with PLC (Programmablelogical control system) which can control the equipment automatically to everystage of its process and ensure its process and ensure its safe operation onsite and on line without human supervision.

10. Can be operated both on-lineand off-line.

Advantage:

First, it can improve thevoltage and make the every index like acid value, PH value, of the insulationoil reach the national standard by removing the water, impurities and gas fromthe non-conformable oil. Second, it can improve the insulation oil's index,completely filtering the polarity materials like free carbon, deep oxide.

Features:

1. Besides the common vacuum oilpurifier's function of dewatering, degassing, and eliminating impurities, thismachine can regenerate the seriously exhausted oil by removing the polaritymaterials, such as deep oxides, free carbon in the oil effectively. It can makethe seriously exhausted oil reach the normal index like anti-oxidation,acid-base water-solubility.

2. Three ways of using: the vacuum dewatering,degassing, removing impurities system can work independently, so does theregeneration oil system, and also they can work at the same time.

3.Double-stage, high vacuum pressure and high flow rate that help remove water,air, gases, solid particulates and other impurities from oil quickly andefficiently so as to improve the breakdown voltage of oil and maintain itsinsulating property.

4.Advanced dehydrating and degassing system that uselarge area three-dimension flash distillation technique to remove harmfulcomposition in the oil, such as water, air and gases.

5. Precise finemulti-stage filtration helps remove mechanical impurities in oil, high qualityfilter elements is of corrosion proof, strong mechanical strength and wearresistance.

6.The machine adopts the double-infrared liquid automaticcontroller, sensitive automatic pressure protector and the high effectiveequipment for degas, so it is easy to operate.

7. Carbon fiber infraredheating system that can make the oil contains zero sum of ethyne aftertreatment.

8. The oil of any grades can be treated on line at the workingsite.

9. The Automatic oil purifier model is installed with PLC (Programmablelogical control system) which can control the equipment automatically to everystage of its process and ensure its process and ensure its safe operation onsite and on line without human supervision.

10. Can be operated both on-lineand off-line.

Advantage:

First, it can improve thevoltage and make the every index like acid value, PH value, of the insulationoil reach the national standard by removing the water, impurities and gas fromthe non-conformable oil. Second, it can improve the insulation oil's index,completely filtering the polarity materials like free carbon, deep oxide.

Related Search

Filtering Oil System

Transformer Oil Regeneration

Oil Regeneration

Engine Oil Regeneration

Lube Oil Regeneration

Turbine Oil Regeneration

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)