|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Dielectric oil filtration oil purify oil regenerating unit

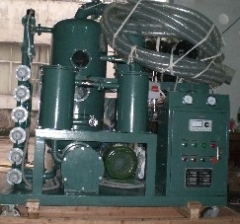

Dielectric oil filtration oil purify oil regenerating unit

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Type:

Oil Purifier

Production Capacity:

100

Delivery Date:

15 DAYS

Brand Name:

ZN

ZYD is special for treating the used and old transformer oil, mutual oil, switch oil.

Application:

This type of machineadopts thermal vacuum dehydration and degasification of electrical insulatingoils in order to withdraw free and soluble waste, gas and to remove particulateseffectively. The product is widely applied to areas of power station, powercompany, transformer substation, railway, petroleum, chemical andmetallurgy.

The product is also aspecial facility of electric power and industrial enterprises for treatment ofvarious insulation oils including non-conformable transformer oil, mutualinductor oil and circuit breaker oil, as well as a best choice for vacuum oilingof power equipment and drying of moisture of power equipment.

Features:

1.Duplex-Stereo filmevaporation technology, combined with unique and advanced dewatering, degassingcomponents, can rapidly and effectively separate water, gas from oil.

2.Multi-stage precision filtration system, mesh filtration combined with molecularadsorption technologies

3. Efficient electric heating system, heatinguniformity, less power consumption, safe, and reliable.

4. Double-infraredliquid level sensor, pressure protective system to ensure the machine operationeasy and safely.

5. Adopts interlocked protective system, which connect oilpump, heater and liquid level sensor, avoiding blank heating, blank pumping, oilleak and electricity leak. If there is any fault, machine will be power offautomatically.

6. Working with BZ insulating oil regeneration device todecolor (remove acid, oxide, free carbon) and lower dielectric loss, making thetreated oil more limpidity.mining enterprises purifying the unqualifiedtransformer oil, mutual inductor oil, switch oil and so on.

2.Multi-stage precision filtration system, mesh filtration combined with molecularadsorption technologies

3. Efficient electric heating system, heatinguniformity, less power consumption, safe, and reliable.

4. Double-infraredliquid level sensor, pressure protective system to ensure the machine operationeasy and safely.

5. Adopts interlocked protective system, which connect oilpump, heater and liquid level sensor, avoiding blank heating, blank pumping, oilleak and electricity leak. If there is any fault, machine will be power offautomatically.

6. Working with BZ insulating oil regeneration device todecolor (remove acid, oxide, free carbon) and lower dielectric loss, making thetreated oil more limpidity.mining enterprises purifying the unqualifiedtransformer oil, mutual inductor oil, switch oil and so on.

Advantage:

Comparing with thesingle-stage type, this machine adopts the double stages vacuum system, whichcan improve the machines working vacuum value highly, so it can dewater, degasand remove the impurity more deeply and effectively. The dielectric value oftreated oil is higher than 75 KV. It is very suitable for the large electric& insulation equipments.

Comparing with thesingle-stage type, this machine adopts the double stages vacuum system, whichcan improve the machines working vacuum value highly, so it can dewater, degasand remove the impurity more deeply and effectively. The dielectric value oftreated oil is higher than 75 KV. It is very suitable for the large electric& insulation equipments.

Related Search

Oil Filtration

Filtration Oil

Hydraulic Oil Filtration

Engine Oil Filtration

Lubricant Oil Filtration

Transformer Oil Filtration

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)