|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Transformer Oil Filtration Oil Filters Oil Refiner Machine

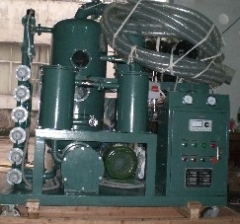

Transformer Oil Filtration Oil Filters Oil Refiner Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Brand Name:

ZN

Production Capacity:

100

Delivery Date:

15 DAYS

ZYD is special for treating the used and old transformer oil, mutual oil, switch oil.

It is suitable for oil recycling or oil filtration for transformer oil

1.Series ZYD Double-stage transformer oil purifier can quickly removewater, trace water, gas, particles as well as acetylene, hydrogen, methane andother harmful ingredients from oil effectively to improve oil's dielectricstrength, effectively making sure electric equipments working safely andnormally.

1. Double-stage vacuum system, strong power of vacuum evacuating,ultimate vacuum value ≤ 5Pa.

2. Two vacuum separating chambers, efficientoil film sprayer, increasing separating size and separating time to ensure thedry-level and dielectric strength improving greatly.

3. Duplex-Stereo filmevaporation technology, combined with unique and advanced dewatering, degassingcomponents, can rapidly and effectively separate water, gas from oil.

4.Multi-stage precision filtration system, mesh filtration combined with molecularadsorption technologies.

5. Efficient electric heating system, heatinguniformity, less power consumption, safe, and reliable.

6. Double-infraredliquid level sensor, pressure protective system to ensure machine operation easyand safely.

7. Adopt interlocked protective system, which connect oil pump,heater and liquid level sensor, avoiding blank heating, blank pumping, oil leakand electricity leak. If there is any fault, machine will be power offautomatically.

8. Functions of live line work onsite, vacuum drying andvacuum oil filling.

Transformer Oil Filtration Machine

They are suitable for oil treatment, vacuum oil injection, andcyclic hot-oil drying in the installation and maintenance of bigtransformers.

Oil Treatment Index:

1. Dielectrical Strength: 70-75KV

2. Water Content:3~5ppm

3. Gas Content:≤0.2%

4. Particles Suspended: 1-3µm

Application:

1.Series ZYD Double-stage transformer oil purifier can quickly removewater, trace water, gas, particles as well as acetylene, hydrogen, methane andother harmful ingredients from oil effectively to improve oil's dielectricstrength, effectively making sure electric equipments working safely andnormally.

2.Series ZYD oil filter is particularly suitable for treating high-gradetransformer oil, super-voltage transformer oil and new transformer oil. It canbe used for filtration of more than 110V substation live line work onsite.Meanwhile,

3.Series ZYD oil filtration system can be used as independent vacuum sourcewith functions of vacuum drying and vacuum oiling.

Features:

Features:

1. Double-stage vacuum system, strong power of vacuum evacuating,ultimate vacuum value ≤ 5Pa.

2. Two vacuum separating chambers, efficientoil film sprayer, increasing separating size and separating time to ensure thedry-level and dielectric strength improving greatly.

3. Duplex-Stereo filmevaporation technology, combined with unique and advanced dewatering, degassingcomponents, can rapidly and effectively separate water, gas from oil.

4.Multi-stage precision filtration system, mesh filtration combined with molecularadsorption technologies.

5. Efficient electric heating system, heatinguniformity, less power consumption, safe, and reliable.

6. Double-infraredliquid level sensor, pressure protective system to ensure machine operation easyand safely.

7. Adopt interlocked protective system, which connect oil pump,heater and liquid level sensor, avoiding blank heating, blank pumping, oil leakand electricity leak. If there is any fault, machine will be power offautomatically.

8. Functions of live line work onsite, vacuum drying andvacuum oil filling.

Related Search

Transformer Oil Filtration

Oil Filtration

Filtration Oil

Oil Filters

Hydraulic Oil Filtration

Engine Oil Filtration

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)