|

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd

|

Gold Index: 18132

You are here: home > OIL PURIFIER > Transformer Oil Purifier > Insulation oil dehydration oil reclaiming waste oil management machine

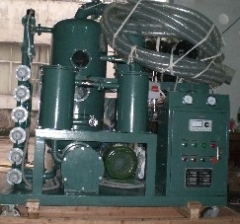

Insulation oil dehydration oil reclaiming waste oil management machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

ZYD

Packing:

WOODEN CASE

Brand Name:

ZN

Production Capacity:

100

Delivery Date:

15 DAYS

ZYD is special for treating the used and old transformer oil, mutual oil, switch oil.

To remove free, soluble water, carbon, free and dissolved gases and particulatematters, dust from insulating oil effectively and rapidly.

Structure

Dehydration (Degas) System

1, The vacuum chamber hasflash tower, which can evaporate the water efficiently. Also it has the sprayingnozzle with degassing elements design. The heater, being placed on the vacuumvessel, becomes an evaporator. Thus the flash tower of vacuum vessel is threetimes more than that of the general vacuum vessel. This innovation can dehydrateand degas effectively and efficiently.

2, The optimal structure of thedehydration (degas) system enlarges the surface area of oil exposed to thevacuum system and extends the flowing distance of the oil in the vacuum system.Thus there has sufficient time to remove the moisture and gas from the oil byvaporization.

With Vacuum pumpand Roots pump.

Enhance the value of breakdown voltage greatly.

Easyhandling and maintenance.

Inject oil into the transformers.

Lowermaintenance and replacement expenses.

Automatic reverse-washing system willextend the lifetime of filters and improve the performance of thefilters.

High performance security system including pressure protectiondevice and automatic temperature controller makes purifier operatesafely.

Utilizes coacervation technology, coalescing technology, separatingtechnology and refined purification technology. To remove free, soluble water,carbon, free and dissolved gases and particulate matters from insulating oileffectively and rapidly.

Enhance the value of breakdown voltage greatly.

Easyhandling and maintenance.

Inject oil into the transformers.

Lowermaintenance and replacement expenses.

Automatic reverse-washing system willextend the lifetime of filters and improve the performance of thefilters.

High performance security system including pressure protectiondevice and automatic temperature controller makes purifier operatesafely.

Utilizes coacervation technology, coalescing technology, separatingtechnology and refined purification technology. To remove free, soluble water,carbon, free and dissolved gases and particulate matters from insulating oileffectively and rapidly.

Structure

Dehydration (Degas) System

1, The vacuum chamber hasflash tower, which can evaporate the water efficiently. Also it has the sprayingnozzle with degassing elements design. The heater, being placed on the vacuumvessel, becomes an evaporator. Thus the flash tower of vacuum vessel is threetimes more than that of the general vacuum vessel. This innovation can dehydrateand degas effectively and efficiently.

2, The optimal structure of thedehydration (degas) system enlarges the surface area of oil exposed to thevacuum system and extends the flowing distance of the oil in the vacuum system.Thus there has sufficient time to remove the moisture and gas from the oil byvaporization.

Related Search

Waste Oil

Waste Oil Pump

Waste Oil Filter

Waste Oil Recycling

Waste Engine Oil

Waste Oil Filtration

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Chn Chongqing Zhongneng Oil Purifier Manufacture Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Chongqing

Province/State: Chongqing

Country/Region: China (Mainland)

You May Like:

Product (300)

- OIL PURIFIER (300)